Planning to achieve your goals

It is that time of the year again, when we make our New Year’s resolutions. The most common resolutions involve weight loss and/or fitness. If this isn’t your resolution this year, it has most likely been one previously. And, like most people across the world, you very likely failed at meeting your goal.The reason for the failure is threefold: First, instead of a detailed goal, you had a dream; secondly, there was no plan in place to achieve the goal; and thirdly, you did not have ways to measure ongoing progress. Business works the same way. The only way to achieve organisational goals, such as increasing sales or market share growth, is to have all three of these things in place.The best way to illustrate this is with an example: A dream would be wanting to lose weight, or becoming more fit. A business dream would be to improve sales. A goal, with the related metrics, should be SMART, see this article for more on this topic. So, back to our examples: a weight loss goal would be to lose 10% of your weight by the end of the year, and a fitness goals would be to run a marathon by the end of the year. These would be measured by weekly weigh-ins; and total kilometres ran each month.Similarly, the business goal would be to increase sales by 10% for the financial year, and the associated metric would be sales per month, compared to the previous year.

High-level Plan

Now that the goals and measures have been established, you will need a plan. Based on our fitness example, your high-level plan could include:- 3 runs per week

- 2 weight-training sessions per week

- Slowly increasing your speed

- Increasing the distance run by 10% every other week

- Increasing sales to current customers

- Finding new customers

- Developing new products to entice current customers

- Developing new products to entice new customers

Demand Plan

The demand plan takes the high-level plan and spreads it across the year. The demand plan will take into account seasonality, for instance festive season peaks, as well as other historical demand patterns. It will also take into account when new products are launched, and additional sales for new customers.Your demand plan is what the organisation commits to, much like you create commitment by paying your entrance fee for an end-of-year marathon at the beginning of the year.Rough Cut Capacity Plan (RCCP)

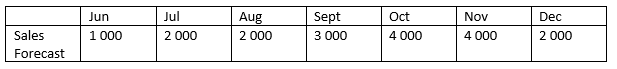

Now that you have committed to the year-end marathon, you can start looking at how many kilometres you need to run each month and, thus, each week, to build up to being able to do 42 km in one stretch. This may make you realise that you need additional resources, such as a treadmill or a gym membership, for those times when running outside is not possible, as well as weights for cross training.In the same way you would plan out your monthly kilometre requirements, RCCP is about determining when you are going to make your products to meet the demand set out in the demand plan. Much like your fitness plan requires resources, the RCCP takes resource availability into account. These resources include material, labour, space, and transport. The RCCP will use the resource availability to pull forward the production, to ensure that demand is met. This is best illustrated by an example. The table below shows the assumed monthly demand for the end of the year:

The RCCP will use the resource availability to pull forward the production, to ensure that demand is met. This is best illustrated by an example. The table below shows the assumed monthly demand for the end of the year: Let’s assume the available monthly manufacture capacity is 3 000 units per month, except for December. The manufacturing capacity in December is limited to 2 000 units, due to the annual shut-down. Let’s also assume that the units must be manufactured in the month prior to the demand. As you can see the demand for October and November cannot be met. So, to meet the demand for these months, stock needs to be built up, by manufacturing 3 000 units in June, July, and August.

Let’s assume the available monthly manufacture capacity is 3 000 units per month, except for December. The manufacturing capacity in December is limited to 2 000 units, due to the annual shut-down. Let’s also assume that the units must be manufactured in the month prior to the demand. As you can see the demand for October and November cannot be met. So, to meet the demand for these months, stock needs to be built up, by manufacturing 3 000 units in June, July, and August.

Material Requirements Planning (MRP)

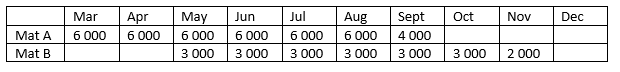

Now that the manufacturing requirements have been determined, you would plan the detailed material requirements. This would include producing components and buying inputs. Using the same example as above, it is clear that we need material for the 3 000 items.

Let’s assume each need item needs 2 units of material A and 1 unit of material B. Then, let’s work with a lead time of 2 months for material A, and a lead time of a couple of days for material B. This would mean that the ordering would look something like this:

Material B would be ordered at least a week prior to requirements, but Material A will need to be ordered in March for the June production run. This simple example does not take issues such as transportation constraints into account, but does clearly show the need for ongoing rolling planning.

Material B would be ordered at least a week prior to requirements, but Material A will need to be ordered in March for the June production run. This simple example does not take issues such as transportation constraints into account, but does clearly show the need for ongoing rolling planning.